6 Must‑Have 3D‑Printed Accessories for the DJI Osmo Pocket 3

Turn Your 3-D Printer, Laser & CNC Into a Revenue Machine

Why 3D Scanning?

3D scanning is an incredible tool for capturing real-world objects and turning them into digital models. Whether you're replicating parts, designing custom enclosures, or reverse-engineering products, the ability to scan and create accurate 3D models opens up countless possibilities.

For this project, I wanted to scan some Milwaukee M12 tools to design and 3D print custom storage trays. Instead of measuring and modeling everything manually, I used the Einstar Vega scanner to create precise digital replicas—saving time and improving accuracy.

Setting Up the Einstar Vega

Before diving into scanning, it’s important to calibrate the device. While calibration isn’t required for every scan, Einstar recommends doing it weekly to maintain accuracy—especially after a firmware update. The process involves using a calibration board that comes with the scanner and following on-screen instructions to align the scanner properly.

Key Takeaway: If you want the best possible scan results, make calibration a regular part of your workflow.

The Scanning Process

With the scanner calibrated, it was time to scan my Milwaukee rotary tool. Since 3D scanners work best with stable objects, I used a lazy Susan to rotate the tool smoothly while scanning. This allowed the scanner to capture multiple angles without me having to move the scanner itself.

Choosing the Right Mode

- HD Mode: Best for small, high-detail objects (which I used for this project).

- Fast Mode: Ideal for larger objects where detail isn’t as critical.

As I rotated the tool, I monitored the scanner’s feedback:

- Green areas indicated high-quality scan data.

- Red areas means missing or low-quality data.

To fill in gaps, I flipped the tool over and scanned it from additional angles. If the scanner ever lost tracking, a quick backtrack helped it regain its reference points.

Pro Tip: If your object has dark or reflective surfaces, adjusting the exposure settings can improve the scanner’s ability to capture detail.

Turning the Scan into a 3D Model

Once I had a complete scan, I processed the data using Einstar’s software to generate a high-resolution mesh model. This digital version of my tool could now be used in CAD software to design a perfect-fitting storage tray.

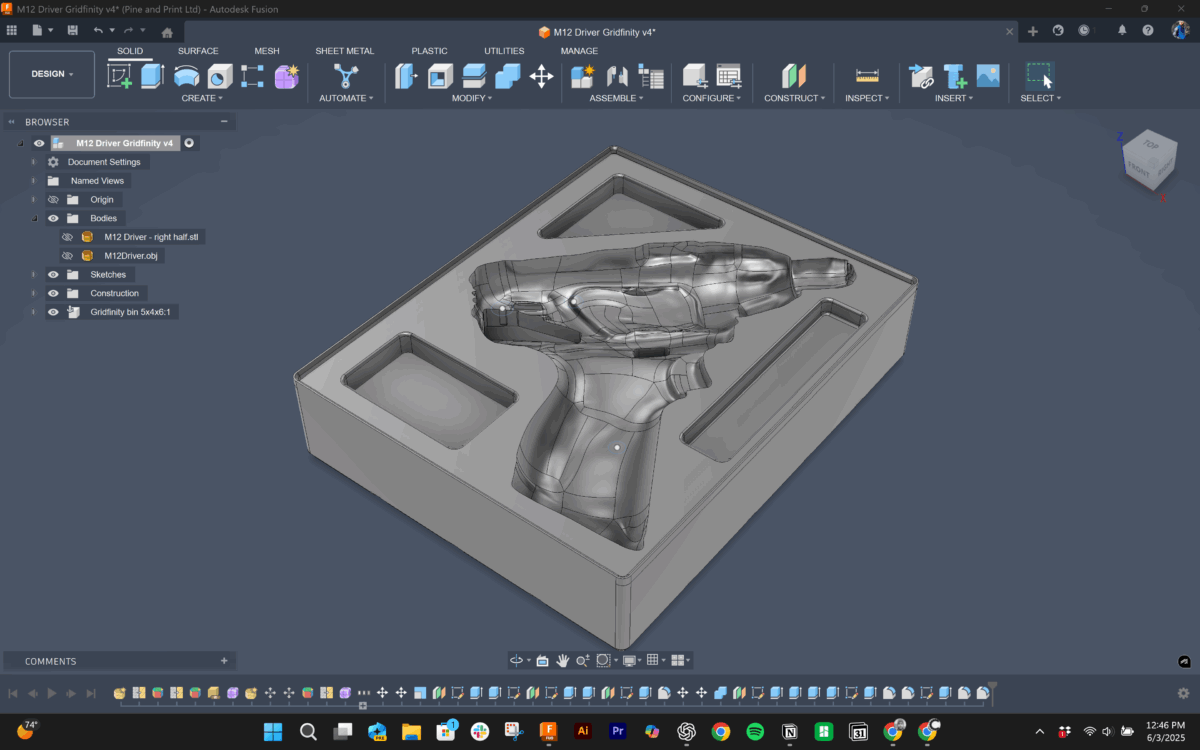

After exporting the scan, I imported it into Fusion 360, where I built a custom tool holder around it. Once the design was finalized, I 3D printed the tray—resulting in a precise, secure storage solution.

The Final Result

After some time spent scanning, designing, and printing, I ended up with a custom storage tray that fits my Milwaukee rotary tool perfectly. Not only does it securely hold the tool, but I also included compartments for additional bits and accessories.

Seeing how well this process worked, I quickly moved on to designing another tray for my Milwaukee battery drill—and I can already tell I’ll be using this workflow for many more tools in my shop.

Supporting Images You Might Include:

- A photo of the Einstar Vega scanner in action.

- A screenshot of the scanning software showing a completed scan.

- The final 3D model in Fusion 360.

- The finished 3D-printed storage tray with tools inside.

Why This Matters for Makers

For anyone who loves designing and building, 3D scanning eliminates guesswork and improves precision. Instead of measuring by hand or working from rough sketches, you can digitize objects quickly and work directly with accurate models. Whether you're an engineer, hobbyist, or small business owner, this technology opens up entirely new possibilities for fabrication, prototyping, and organization.

Watch the Full Process

If you want to see this entire process in action, check out my full video on the Crafted With Machines YouTube Channel! I walk through the scanning, modeling, and printing steps in real-time. Be sure to subscribe to my YouTube channel for more content on 3D scanning, CNC work, laser cutting, and other digital fabrication techniques.

Have you experimented with 3D scanning? Let me know in the comments how you’ve used it or what you’d like to see scanned next!

Duplicating an object with the push of a button sounds like science fiction, but 3D scanning kind of makes it a reality. In this post, I’ll show how the Einstar Vega 3D scanner allowed me to create custom storage solutions for tools—and why this technology can transform your workflow.

Why 3D Scanning?

3D scanning captures real-world objects and converts them into digital models. Whether replicating parts, designing custom enclosures, or reverse-engineering products, scanning creates accurate 3D models efficiently.

For this project, I scanned Milwaukee M12 tools to design and 3D print custom storage trays. Instead of manually measuring and modeling, the Einstar Vega scanner produced precise digital replicas—saving time and improving accuracy.

Setting Up the Einstar Vega

Calibration ensures accurate scans. Einstar recommends weekly calibration, especially after firmware updates. The process uses a provided calibration board, and on-screen instructions guide the alignment process.

Key Takeaway: Regular calibration optimizes scan quality.

The Scanning Process

After calibration, I scanned a Milwaukee rotary tool. Stable positioning enhances scan accuracy, so I used a lazy Susan to rotate the tool smoothly while keeping the scanner stationary.

Choosing the Right Mode

- HD Mode: Captures fine details (ideal for this project).

- Fast Mode: Suitable for larger objects needing rough scans (I use Fast Mode a lot for scanning people).

Rotating the tool revealed scan quality:

- Green areas indicated complete data.

- Red areas signaled missing or poor data.

To fill gaps, I flipped the tool and scanned from additional angles. If the scanner lost tracking, backtracking slightly helped it regain reference points.

Pro Tip: Adjust exposure settings when scanning dark or reflective surfaces to improve data capture.

Turning the Scan into a 3D Model

After scanning, I processed the data in Einstar’s software to generate a high-resolution mesh model. This digital replica was then imported into Fusion 360 to design a storage tray. Once finalized, I 3D printed the tray for a precise, secure fit.

The Final Result

The completed custom storage tray perfectly fits the Milwaukee rotary tool. Additional compartments store bits and accessories.

Encouraged by the success, I designed another tray for a Milwaukee battery drill. This workflow will help optimize storage for many more tools in the shop.

Why This Matters for Makers

For designers and builders, 3D scanning eliminates guesswork and improves precision. Instead of manual measurements, digitized objects enable accurate modeling. Engineers, hobbyists, and small business owners can leverage this technology for fabrication, prototyping, and organization.

Watch the Full Process

To see the entire process in action, check out my full video on Crafted With Machines! The video walks through scanning, modeling, and printing in real-time. Subscribe to my YouTube channel for more content on 3D scanning, CNC work, laser cutting, and digital fabrication techniques.

Want the files to print for your own shop? Head over to our Patreon to snag the files for Free.

Have you tried 3D scanning? Share your experiences and suggestions in the comments!